The ACE is an airport combination machine for de-icing runways, taxi-ways and aprons and is available in four different versions to meet differing needs. With the ACE range, solid and liquid spreading materials can be applied separately or combined in a single operation, and it is designed for mounting on large carrier vehicles and semi-trailers.

Product variants

ACE-2S – The basic version

For airports wanting a de-icing solution that adapts ideally to every situation, the smart ACE-2S concept is a great entry-level variant. Thanks to the special spreading discs, both spreading and spraying materials can be applied.

- Two special spreading discs to the rear

- Spreading width of 6 m to 24 m

- Spraying width of 6 m to 15 m

ACE-ASPS – The entry-level variant with nozzles

The ideal solution for airports that want precise spraying and have less de-icing time pressure.

- Two special spreading discs to the rear

- Fixed spray bar to the rear

- Two side spraying arms at the front with a single row of nozzles

- Spreading width of 6 m to 24 m

- Spraying width of 6 m to 16 m or even 24 m using long ejection nozzles

ACE-ASP – The professional version with nozzles

The ACE-ASP offers ideal features for airports wanting fast and accurate spraying. It combines the proven technology of the ACE-2S with state-of-the-art ASP spraying technology

- Two special spreading discs to the rear

- Fixed spray bar to the rear

- Two side spraying arms at the front with a double row of nozzles

- Spreading width of 6 m to 24 m

- Spraying width of 4 m to 14 m or 24 m

ACE-RSP – The disc variant

A handy and low-maintenance solution with four special spreading discs in total.

- Two special spreading discs to the rear

- Two side spraying arms, each fitted with one spreading disc

- Spreading width of 6 m to 24 m

- Spraying width of 6 m to 15 m or 24 m

Modular construction

The ACE is designed for mounting on large carrier vehicles and semi-trailers and, due to its modular construction, can be assembled in many different ways to meet the individual requirements of different airports.

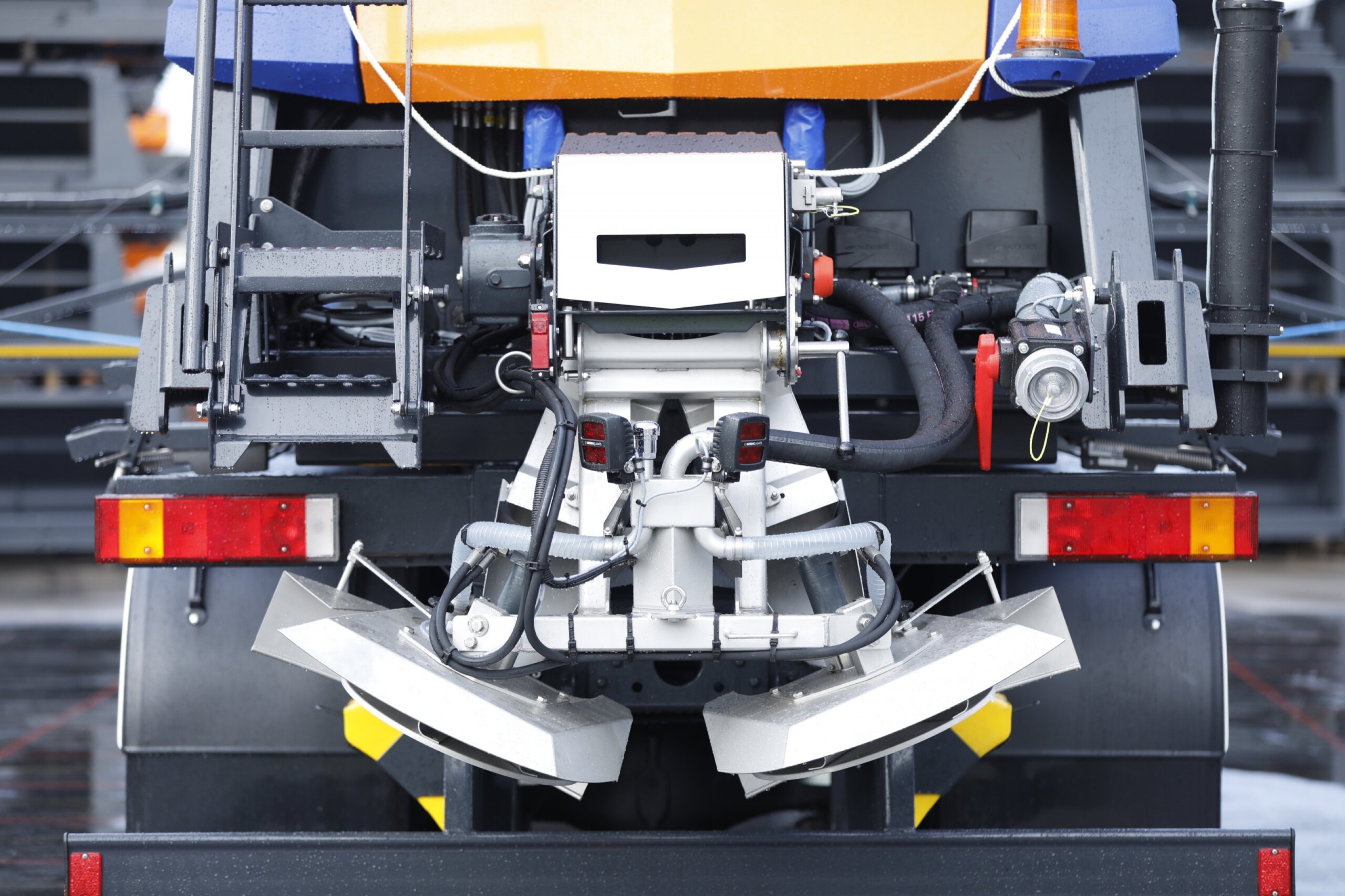

The combination machine consists of three components: the body with modular liquid tanks made of polyethylene, the drive unit, and the separate spreading material container with a distribution system. There are only a few wearing parts. and the entire machine benefits from specially developed corrosion protection, while all joints are hermetically sealed.

Hopper

The ACE’s hopper has a volume from 4.0-7.0m³ while the polyethylene system tanks are suitable for any spraying agent. They are available from 1,850 litres and can be supplemented with 2,200 or 2,500 litre front tanks. The hopper and tank configurations can be adapted to suit different vehicles and local conditions.

Dosage and conveyor system

The spreading material is transported to the distribution system by a V-profiled conveyor belt. Pressure distributors relieve the pressure of the spreading material on the belt ensuring a long service life.

Distribution system

For all ACE variants, a double-disc spreading system allows solid, liquid or mixed spreading materials to be used. The spreading agent is delivered via a conveyor belt and liquid pump, based on the vehicle’s speed. Mixtures of solid and liquid spraying materials can be applied up to a ratio of 1:1 (50% solid and 50% liquid) thanks to a special injection system, while closed control loops allow precise distribution of the de-icing agent.